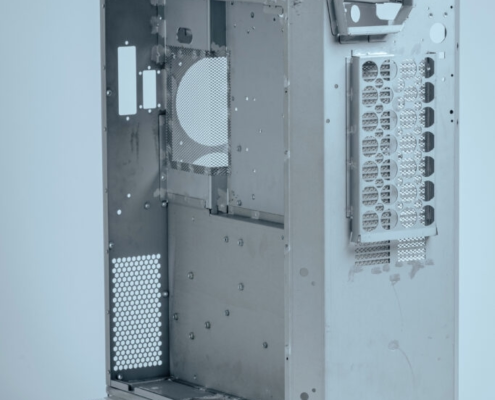

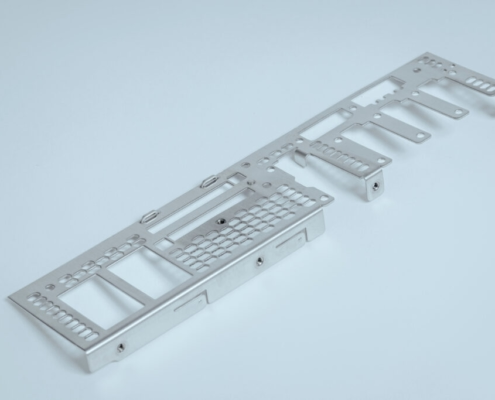

In the development and production of sheet metal enclosures, we utilize a wide range of advanced technologies including CNC sheet metal punching, laser cutting, CNC bending, CNC milling and turning, surface treatments (galvanic, powder coating, printing), welding and grinding, as well as stamping with hydraulic and eccentric presses, all supported by our in-house tool shop.

We assemble complex enclosures, allowing our customers to focus solely on the final assembly of electronics. Our extensive range of services and technologies ensures that we can meet all your sheet metal enclosure needs efficiently and with highest quality. The combination of CNC technology and pressing machines enables us to offer optimal technological and production solutions for any batch size, ensuring precision, productivity and cost optimization for our clients.

Technologies and Processes

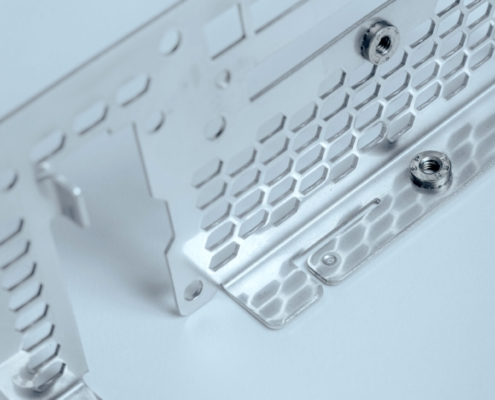

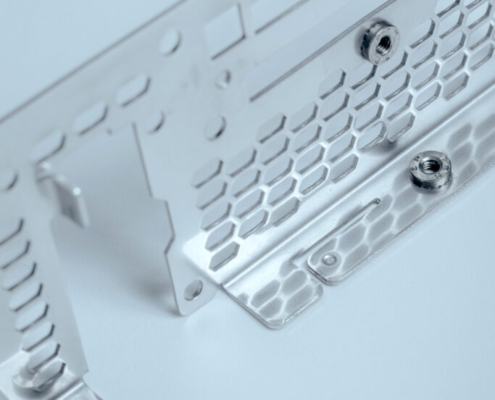

CNC Sheet Metal Punching

Our Trumpf machines enable the production of a diverse range of sheet metal parts from aluminum, steel, stainless steel and copper. In addition to punching, these machines offer the ability to reshape sheet metal parts or create threads. Innovations such as active and descending die technology ensure the highest quality parts and high productivity.

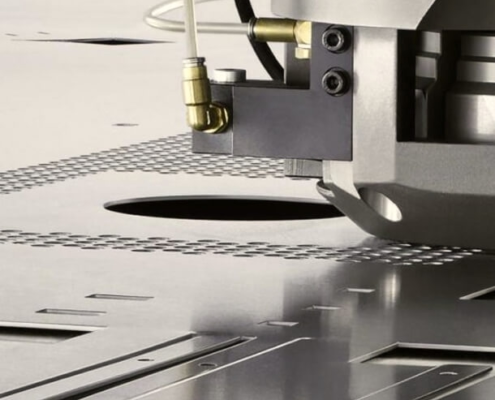

Laser Sheet Metal Cutting

Modern sheet metal forming requires laser cutting technology, which is effective for both thick and thin materials shaped into complex contours. The process requires no tooling, making it particularly attractive for low-volume production. The company uses an automated CO2 laser cutting system, which allows for consistent and precise cutting, even of very thin and flexible materials, without distortion, as well as much more.

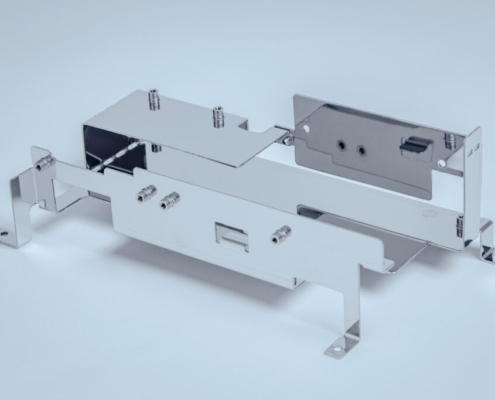

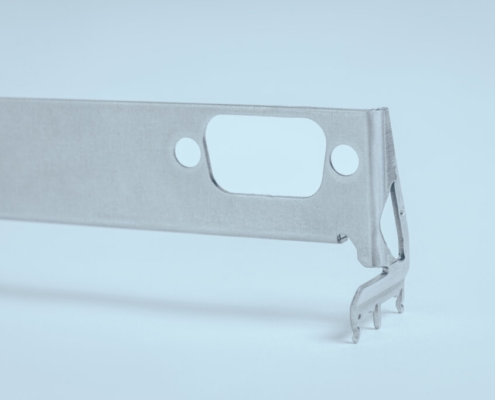

CNC Sheet Metal Bending

Our wide range of bending machines (primarily Trumpf series 5000 and 7000) allows us to perform high-speed bending of small and medium-sized parts (series 7000), with safe and fast operations facilitated by BendGuard Automatic, which autonomously adjusts to the highest tool height setup using the CNC control system. The 5000 series enables the bending of larger parts, achieving high efficiency and an extremely high level of quality due to direct drive and angle measurement systems.

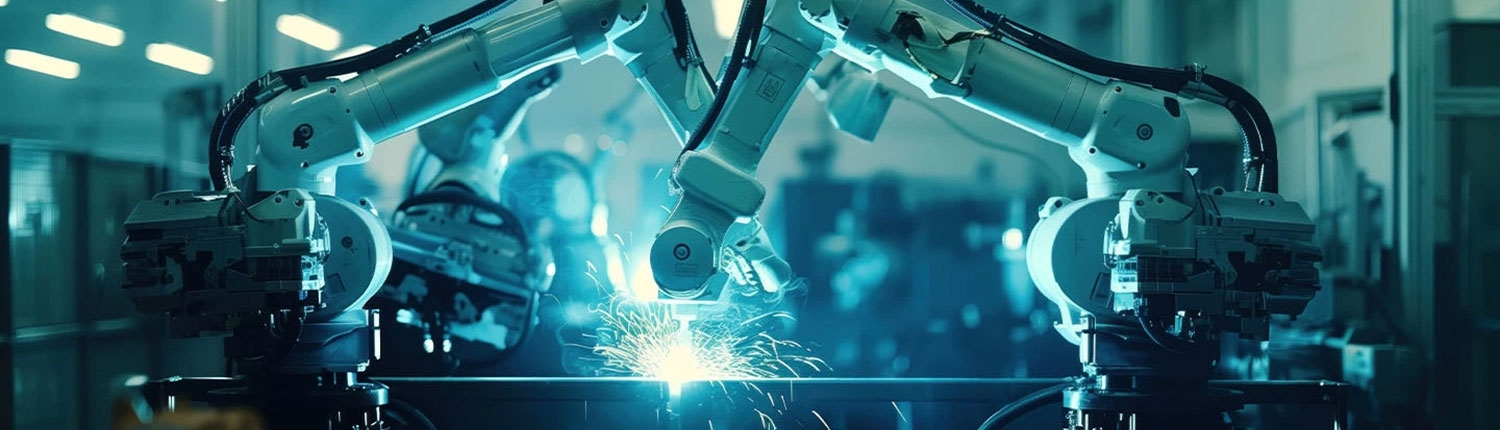

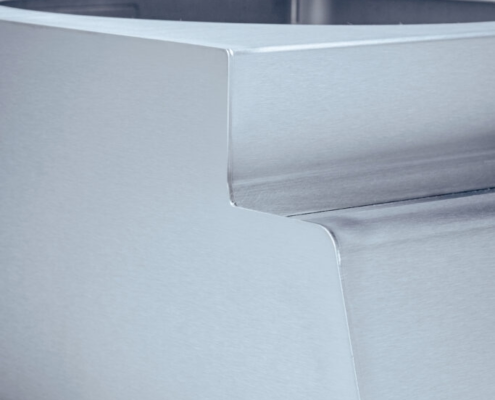

Welding and Grinding

We offer a wide range of welding technologies that enable the welding of steel, stainless steel, and aluminum. In addition to standard TIG, MIG, and MAG welding processes in protective gases. We also offers resistance spot welding, CNC stud welding, and laser welding. Our welding services include grinding and polishing processes for welded metal parts, providing a finished appearance and eliminating any potential imperfections.

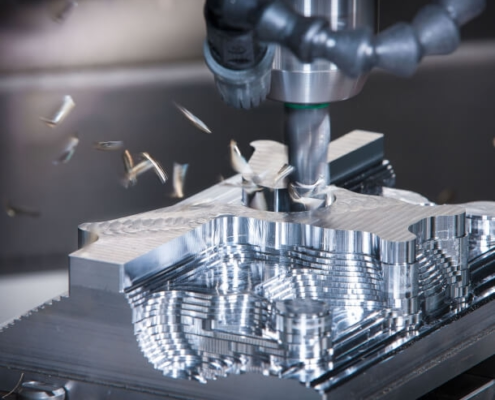

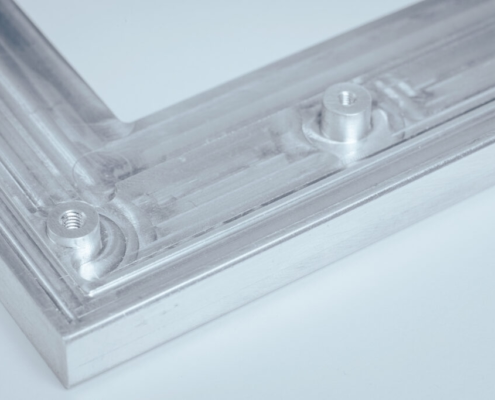

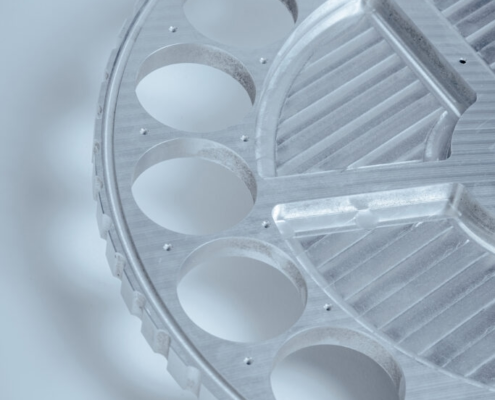

CNC Milling

We provide high-performance, precise and reliable comprehensive milling services, from large-scale processing of medium-sized parts to the machining of smaller components. We can mill various materials, including aluminum, steel, stainless steel, copper, brass and plastics. We produce both aluminum and stainless-steel LCD frames, as well as various subassemblies of complex sheet metal enclosures. The company uses milling machines from Hass, Mazak, and Datron.

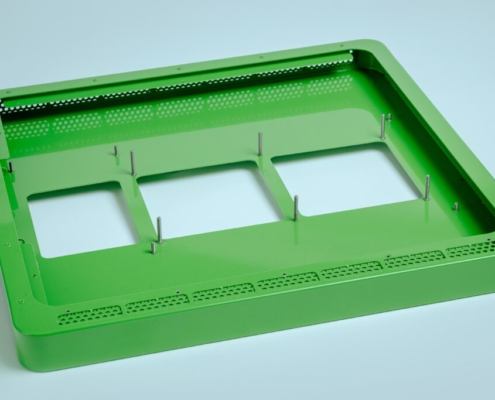

Surface Treatments

We offer a wide range of essential surface treatments that provide surface protection and/or enhance visual appearance. In addition to tampo, screen and digital printing, we also offer sandblasting, grinding and polishing, wet and powder coating, various galvanizing processes (zinc, nickel), and surface treatments such as passivation, anodizing and phosphating. Serving highly demanding sectors, such as medical, the company has specialized in providing top-quality surface treatment services.

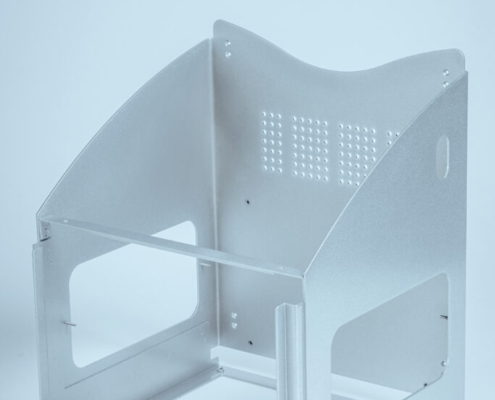

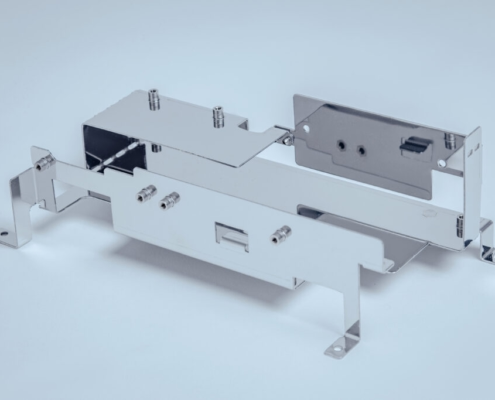

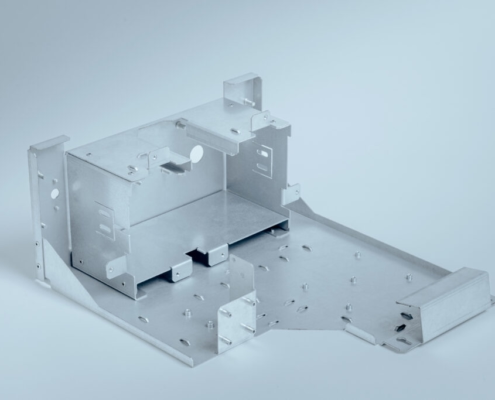

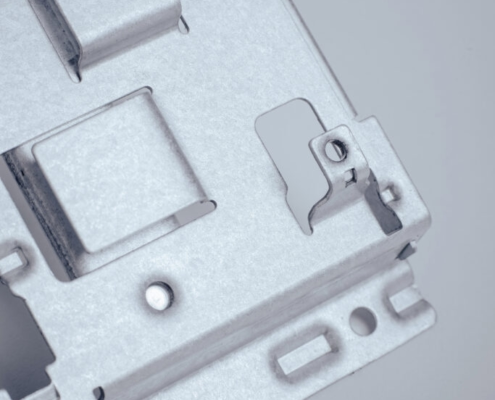

Assembly of Metal Enclosures

We assemble mechanical parts into complete enclosures, add components and can source standard elements to incorporate into your product. This shortens your supply chain, reduces your internal assembly steps and increases flexibility. In addition to assembly, we offer the process of embedding fasteners, deburring and straightening sheet metal parts, cleaning (degreasing), as well as riveting and thread tapping.

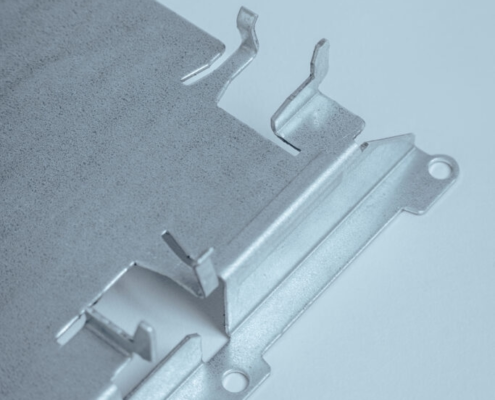

Presses and Tooling

The production of parts using hydraulic and/or eccentric presses (progressive tools) or in combination with CNC technology allows us to offer you an optimal production process for any batch size. We specialize in the production of complex, high-quality components that require extensive expertise and experience. We design, manufacture, assemble and maintain progressive tools for sheet metal parts using milling, EDM and grinding.