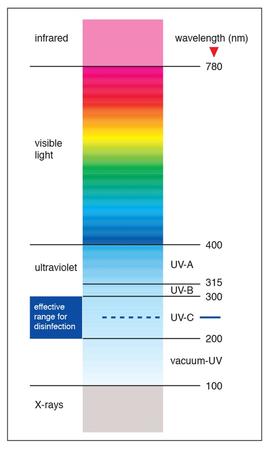

Tabletop UV Ozone Cleaner, Model HELIOS-500High-intensity UV grid lamp (185nm + 254nm)

Tabletop UV Ozone Cleaner, Model HELIOS-500High-intensity UV grid lamp (185nm + 254nm)

5.5×5.5×1.5 inch (140x140mm) Drawer Sample Stage

UV Grid Lamp with Stainless Steel Reflector

Drawer Safety Interlocks

Low cost of ownership

2-Inch OD Exhaust Port

Atmospheric process at room temperature

Digital Process Timer (seconds, minutes, hours)

Digital Hour Counter (tracks UV lamp lifetime)

Very compact and lightweight design (12 lbs.)

300mm UV-Ozone Wafer Cleaner, Model HELIOS-1200High-intensity UV grid lamp (185nm + 254nm)

300mm UV-Ozone Wafer Cleaner, Model HELIOS-1200High-intensity UV grid lamp (185nm + 254nm)

Process up to 12″ x 12″ samples or 300 mm wafers

Comes with different sample/wafer holders (4, 8 and 12 inches)

Ambient temperature at atmospheric pressure

Small and compact foot print

2-inch OD Exhaust Port

Drawer loading mechanism

Digital process timer

UV lamp hour counter

Compact UV Ozone Cleaner, Model ProCleanerVery Compact and Lightweight design

Compact UV Ozone Cleaner, Model ProCleanerVery Compact and Lightweight design

Can process up to 5″x5″x1″ samples

Available in 110V or 220V AC

Very low cost of ownership

Dry, chemical-free process at room temperature

Compact UV-Ozone Cleaner, Model ProCleaner PLUSVery Compact and Lightweight design

Compact UV-Ozone Cleaner, Model ProCleaner PLUSVery Compact and Lightweight design

Can process up to 5″x5″x1″ samples

Available in 110V or 220V AC

Very low cost of ownership

Dry, chemical-free process at room temperature

UV-Ozone Cleaning System, Model UV-208High-density ozone-producing UV grid lamp

UV-Ozone Cleaning System, Model UV-208High-density ozone-producing UV grid lamp

Variable distance between the UV lamp and sample stage

Process up to 8″ x 8″ (200 mm) samples

Low-temperature wafer cleaning

Small, compact foot print

Drawer loading mechanism

Digital process timer, purge timer and UV lamp hour counter

UV-Ozone Cleaning System, Model UV-312High-density ozone-producing UV grid lamp

UV-Ozone Cleaning System, Model UV-312High-density ozone-producing UV grid lamp

Variable distance between the UV lamp and sample stage

Process up to 12″ x 12″ (300 mm) samples

Low-temperature wafer cleaning

Small, compact foot print

Drawer loading mechanism

Digital process timer, purge timer and UV lamp hour counter

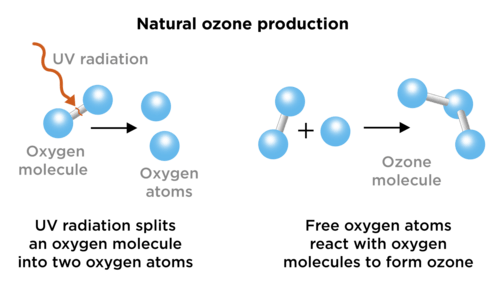

Advantages of UV Surface Cleaning over other surface treatment options

While there are several options for surface cleaning and sample preparation methods, UV-ozone cleaning shows several advantages over other methods.

- Improved wettability resulting in better bonding and coating adhesion

- Does not damage materials

- Simple, fast and cost effective method of cleaning

- Does not induce electrostatic charge on samples

- Low Charging Damage on Substrates

In case of plasma treatment, charging damage caused by ion bombardment can be a serious challenge. It leads to degradation of electrical characteristics of devices. UV-ozone treatment offers surface treatment using oxygen radicals without plasma discharge.

- No Hazardous Effluent

Wet cleaning requires effluent disposal of chemicals. In contrast to the wet cleaning method, UV-ozone treatment is a completely dry and chemical-free process.