Why Wafer ID Readers Are Critical for Semiconductor Traceability

A Look at the Leading Technologies and Market Trends

In the world of semiconductor manufacturing, precision isn’t optional—it’s mission-critical. With 200mm and 300mm wafers worth thousands of dollars each and undergoing hundreds of process steps, the ability to track every wafer’s identity from start to finish is essential to maintaining yield, quality, and accountability. That’s where Wafer ID Readers come into play.

These in-situ or integrated systems automatically read the unique identifiers etched or printed onto wafers—either as alphanumeric OCR marks or 2D Data Matrix barcodes—ensuring that every wafer is processed correctly, matched to its history, and instantly traceable in case of yield excursions.

What Are Wafer ID Readers?

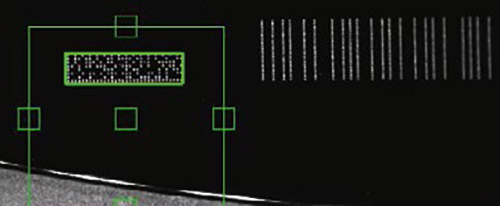

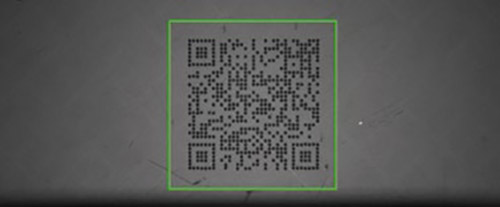

Wafer ID readers are machine vision systems embedded in semiconductor equipment that optically scan wafer IDs. Common mark types include:

- SEMI-standard OCR fonts on the front surface (used especially for 200mm wafers)

- 2D Data Matrix barcodes on the wafer backside (per SEMI T7, standard for 300mm wafers)

These marks can be faint, reflective, and partially degraded from process steps like deposition or CMP. Modern readers overcome these challenges using multi-angle LED lighting, advanced image processing, and AI-enhanced OCR/barcode algorithms.

Why Are They So Important?

- Yield Protection – Misprocessed wafers due to misidentification can result in massive losses. Traceability mitigates that risk.

- Factory Automation – Automated ID verification ensures tools receive and report the right wafer at every step—no manual data entry required.

- SEMI Compliance – Standards like SEMI E90, T7, T5, and T10 require reliable wafer ID systems to ensure data integrity across manufacturing systems.

Who Are the Key Players?

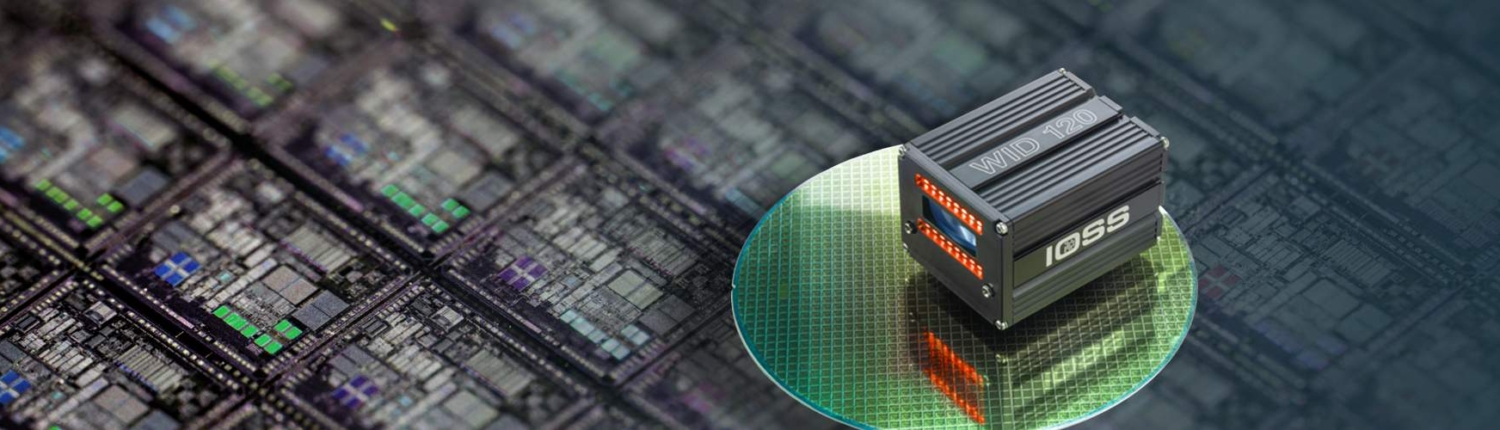

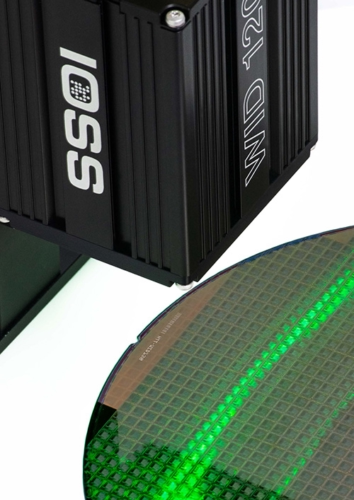

IOSS/HTT Group (Germany) – WID120 Series

WID120 Wafer ID Reader is one of the global leader in semiconductor vision. This versatile and compact reader features built-in processing, multicolor illumination, and SEMI-standard compliance for OCR and Data Matrix reading. Known for its patented 15-mode RGB illumination and simultaneous front/back reading capability, WID120 readers are a preferred choice for fabs needing next generation traceability and maximum reliability. Distributed in the U.S. through partners like UVFAB Systems.

Many automated wafer handlers, aligners, and load ports integrate wafer readers directly—often using IOSS technology under the hood. This plug-and-play approach is common especially in 300mm fabs and foundries worldwide.

Key Takeaways

Wafer ID readers are foundational tools in modern fabs, supporting full traceability and automation.

- The best systems support both OCR and Data Matrix, handle low-contrast or film-covered marks, and integrate cleanly into existing tools.

- Standards compliance—especially SEMI T7, T5, and E90—is a must for seamless MES integration and regulatory alignment.

- Manufacturers like HTT Group and IOSS dominate the global market with proven, fab-ready solutions.

Final Thoughts

As fabs scale for advanced nodes and yield sensitivity increases, wafer ID traceability is no longer a luxury—it’s a necessity. Whether you’re upgrading legacy tools or specifying new equipment, choosing the right wafer ID reader can significantly impact tool utilization, traceability integrity, and your bottom line.

If your fab or tool platform is considering upgrades or evaluations of Wafer ID Readers, reach out to our experts at UVFAB Systems located in Silicon Valley, California.