UV-LED Spot Curing System

Control up to Four UV-LED Curing Heads Independently

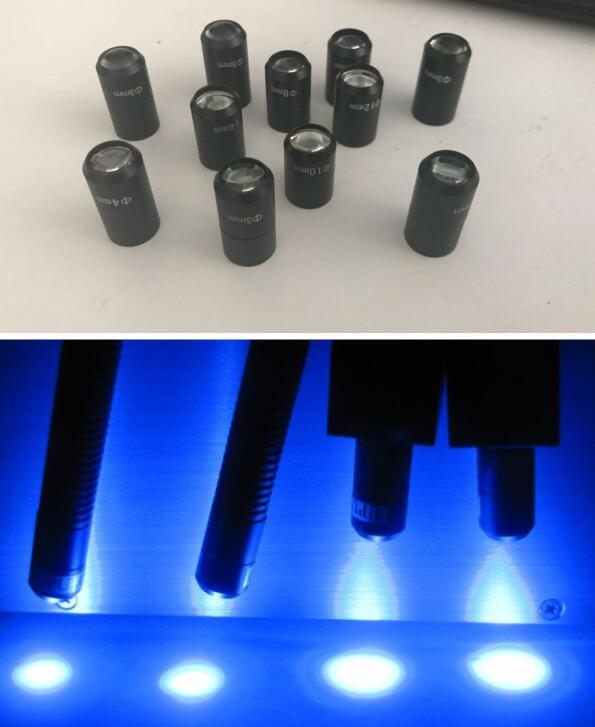

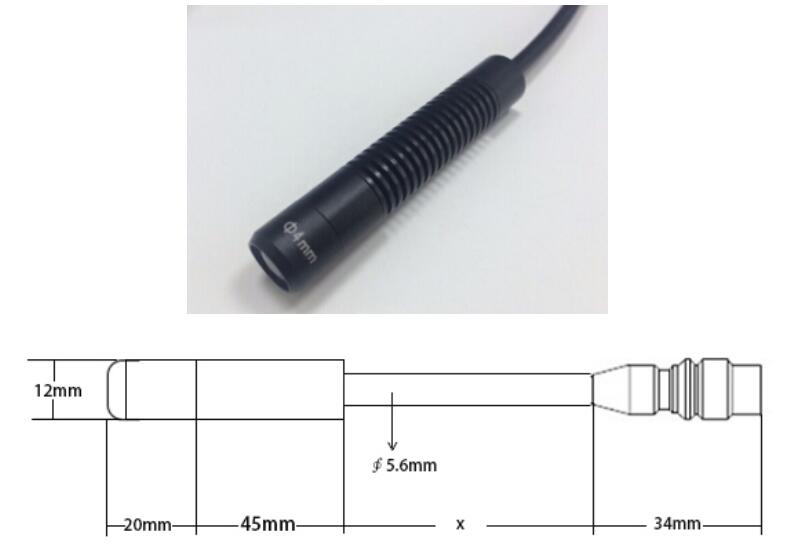

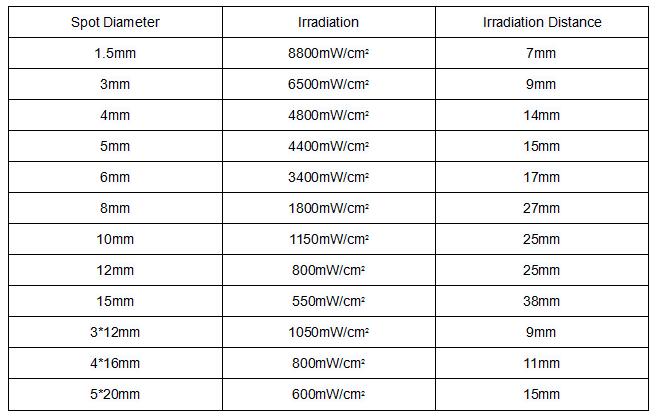

UVFAB’s high-intensity UV LED spot-curing system features all the benefits of UV LED-curing technology in a much smaller, more versatile unit. This system is comprised of a controller with a foot switch and up to four UV-LED heads. UV LED heads are available in 365nm, 385nm, 395nm and 405 nm which can be outfitted with 8mm diameter focusing lenses. LED heads and focusing lenses can be used in any combination and individually controlled. Individual exposure times and intensity settings can be used for each UV LED head, giving users maximum curing flexibility.

UVFAB UV-LED spot curing system generates curing energy using high-intensity UV-LED instead of conventional metal-halide or mercury-arc lamps. The relatively narrow waveband of energy emitted by UV LED results in cooler substrate temperatures compared to traditional UV lamp systems, making them ideal for curing thermally sensitive materials. UVFAB LED UV curing systems offer many energy and cost-saving benefits, such as no warm-up period, lower energy consumption, no bulbs to change, and more consistent wavelength and intensity output for better process control.

In addition to the curing flexibility, this system also features an easy-to-use control interface that allows flexibility in setup and use of the unit. The spot curing system can be activated by a foot pedal or by the user interface.